How to Keep Hydraulic Cylinders in Perfect Sync — Even Under Long Stroke, High Load & High Speed

Ensure Absolute Synchronization in Multi-Cylinder Hydraulic Systems with Confidence

Why Synchronization Is Critical in Modern Hydraulic Equipment

In today’s industrial equipment—such as large presses, heavy-duty injection machines, forging systems, and shipbuilding automation—dual or multiple hydraulic cylinders are often used to drive a shared sliding block (slider). When stroke lengths are long, loads are heavy, and movements are fast, synchronization becomes not just important—but essential.

Even a slight deviation between cylinders can result in:

Uneven force distribution

Slider tilting or deflection

Accelerated wear of guide rails or cylinder seals

Product deformation or equipment damage

Why Synchronization Is Critical in Modern Hydraulic Equipment

In today’s industrial equipment—such as large presses, heavy-duty injection machines, forging systems, and shipbuilding automation—dual or multiple hydraulic cylinders are often used to drive a shared sliding block (slider). When stroke lengths are long, loads are heavy, and movements are fast, synchronization becomes not just important—but essential.

Even a slight deviation between cylinders can result in:

Uneven force distribution

Slider tilting or deflection

Accelerated wear of guide rails or cylinder seals

Product deformation or equipment damage

Key Technical Challenges

Challenge

- Long Stroke

- High Load

- High Speed

Impact

Accumulated error, pressure imbalance

Structural stress, energy loss

Response time delay, control difficulty

4 Proven Synchronization Solutions

1. Closed-Loop Electronic Synchronization (Best for High Precision)

Uses linear displacement sensors and servo valves

Real-time feedback with PLC/servo control system

Accuracy up to ±0.01mm

2. Mechanical Linkage Synchronization

Systems like synchronous shafts or rack-and-pinion

Simple and robust, good for balanced loads

Limitations in stroke length and flexibility

3. Hydraulic Flow Synchronization

Uses flow dividers, synchronous valves, or servo cylinders

Moderate accuracy, but lower cost

Requires precise valve tuning and circuit cleanliness

4. Master-Slave Cylinder Setup

One cylinder drives others via hydraulic balance

Lower cost than full electronic control

Best for semi-automated systems

Best Practices for Engineering Synchronized Hydraulic Systems

✔️ Use identical hydraulic cylinders for symmetry

✔️ Apply low-friction seals for smooth motion

✔️ Reinforce slider with rigid support frames

✔️ Add linear guide rails to reduce deflection

✔️ Design piping layout to avoid flow lag or pressure loss

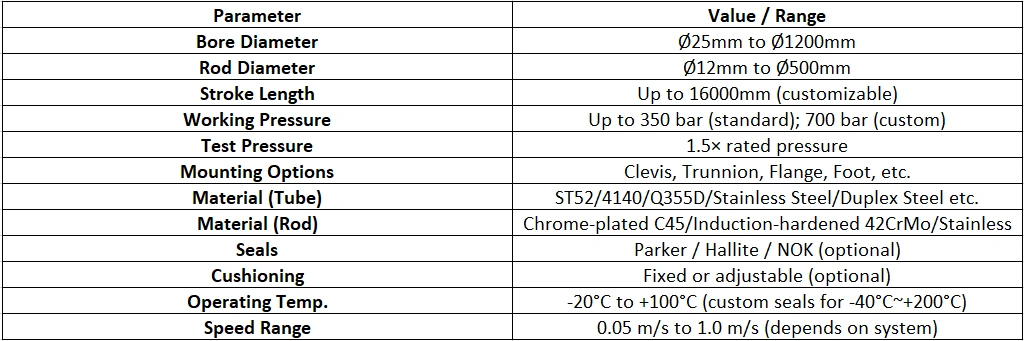

To support demanding hydraulic applications, JW HYDRAULIC offers top-quality Hydraulic Cylinder that contribute to synchronization precision and longevity.