Benefits of Duplex Steel in Marine Hydraulic Applications

Why Duplex Stainless Steel Is Becoming the Preferred Choice for Offshore and Marine Hydraulic Systems

🌊 The Marine Environment: A Challenge for Hydraulic Systems

Hydraulic systems play a vital role in marine and offshore equipment—whether it’s for winches, cranes, steering gear, or deck lifts. However, the harsh saline environment, continuous moisture exposure, and extreme operating pressures demand materials with exceptional strength and corrosion resistance.

What Is Duplex Stainless Steel?

Duplex stainless steel is a family of grades combining the advantages of austenitic and ferritic structures. The result is a material with:

High strength (nearly twice that of 304/316)

Excellent corrosion resistance

Good weldability

High fatigue resistance

Common marine-grade duplex steels include UNS S31803 (2205) and UNS S32750 (Super Duplex 2507).

Key Benefits in Marine Hydraulic Applications

1. 🛡️ Superior Corrosion Resistance in Seawater

Duplex steel offers excellent resistance to:

Pitting and crevice corrosion

Chloride stress corrosion cracking (SCC)

General surface corrosion from salty environments

This makes it ideal for:

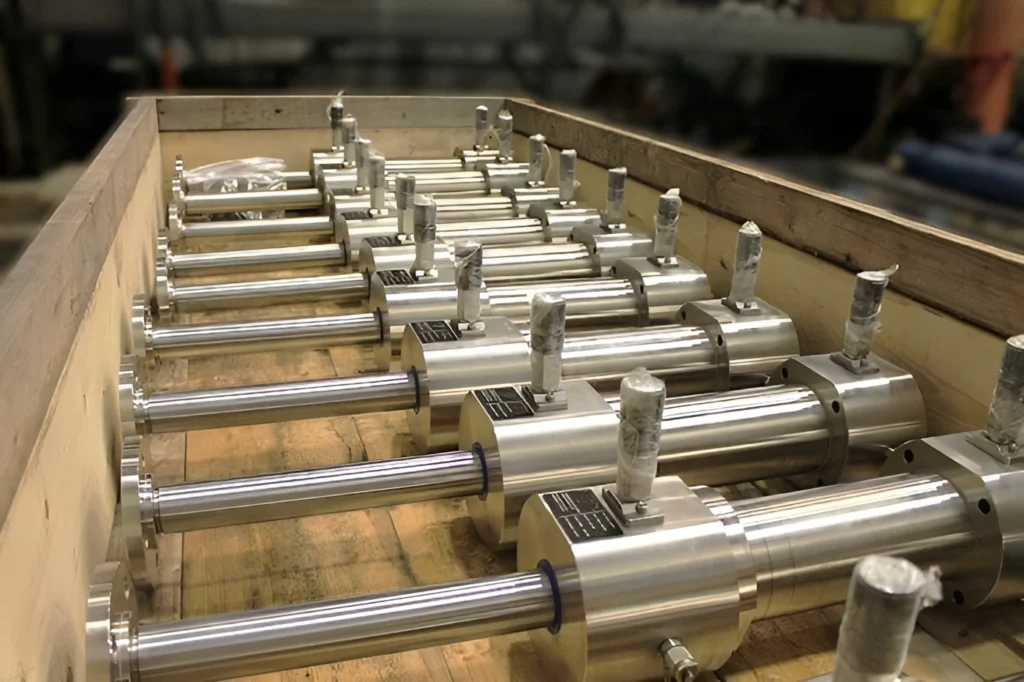

Hydraulic cylinder tubes

Piston rods

Manifolds

Connector fittings

2. ⚙️ High Mechanical Strength

With yield strength up to 450–550 MPa, duplex stainless reduces the wall thickness of cylinders or tubing while maintaining structural integrity. That means:

Lighter equipment

Lower material cost over time

More compact hydraulic systems

3. 🧊 Improved Fatigue and Pressure Resistance

Marine hydraulic systems often undergo:

High-frequency load cycles

Rapid pressure fluctuations

Duplex steel’s fatigue strength helps reduce the risk of:

Cracking

Deformation

Long-term system failure

4. 🛠️ Better Weldability and Machinability

Modern duplex steels are designed to offer:

Stable welding with minimal preheating

Good machinability for precision honed tubes, cylinder heads, and threaded fittings

JW Stainless, for example, supplies duplex honed tubes and rods that are already precision-machined and ready for direct cylinder assembly.

📊 Duplex Steel vs 316L in Marine Use

| Property | 316L Stainless Steel | Duplex 2205 |

| Yield Strength (MPa) | ~220 MPa | ~450 MPa |

| Pitting Resistance (PREN) | ~25 | ~35–40 |

| Chloride SCC Resistance | Moderate | Excellent |

| Fatigue Resistance | Good | Very Good |

| Cost | Lower | Slightly Higher, but cost-effective in long term |

⚓ Real-World Applications of Duplex in Marine Hydraulics

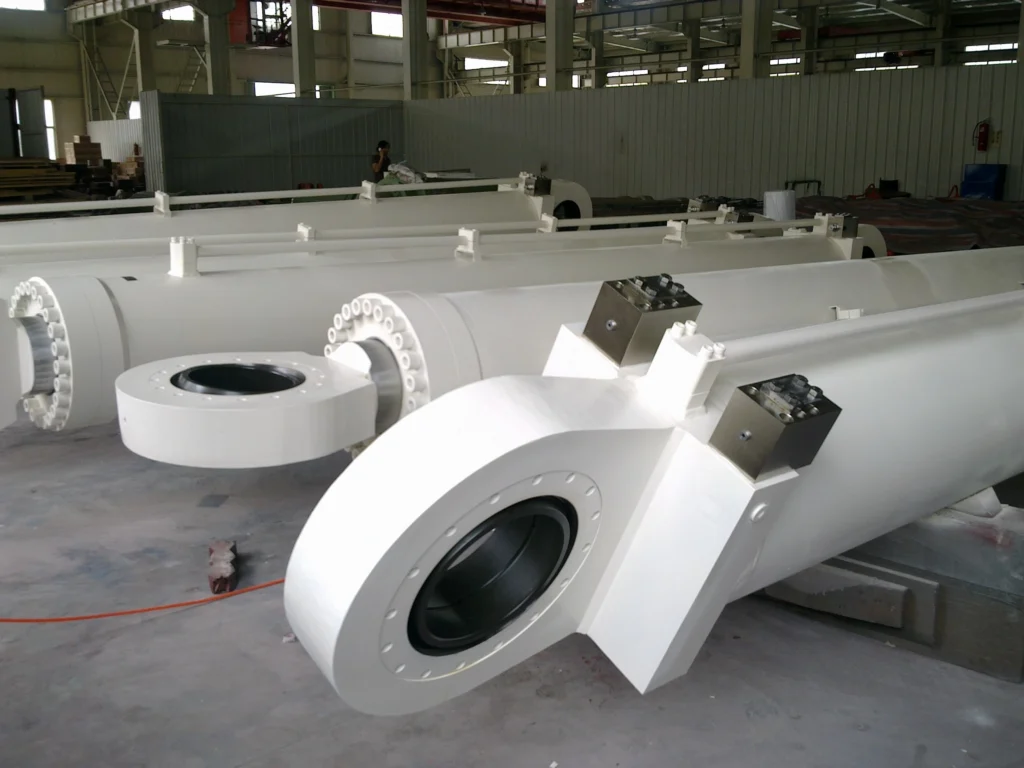

Offshore platforms: Jacking system cylinders, tensioners

Ship deck equipment: Winches, hatches, ramps

Subsea tools: Actuators, ROV manipulators

Marine cranes: High-load lifting cylinders