Water Dam Hydraulic Cylinders – Power and Precision for Heavy-Duty Hydropower Applications

Reliable Hydraulic Solutions for Gates, Spillways, and Flood Control Systems

Description

How Water Dam Hydraulic Cylinders Works ?

Types of Water Dam Hydraulic Cylinders

Single Acting Hydraulic Cylinders

Single acting hydraulic cylinders are designed to generate force in one direction only. In a water dam, they might be used for applications where a simple linear motion in one direction is required, such as raising a sluice gate. The return stroke of the piston is often achieved by the force of gravity or an external spring.

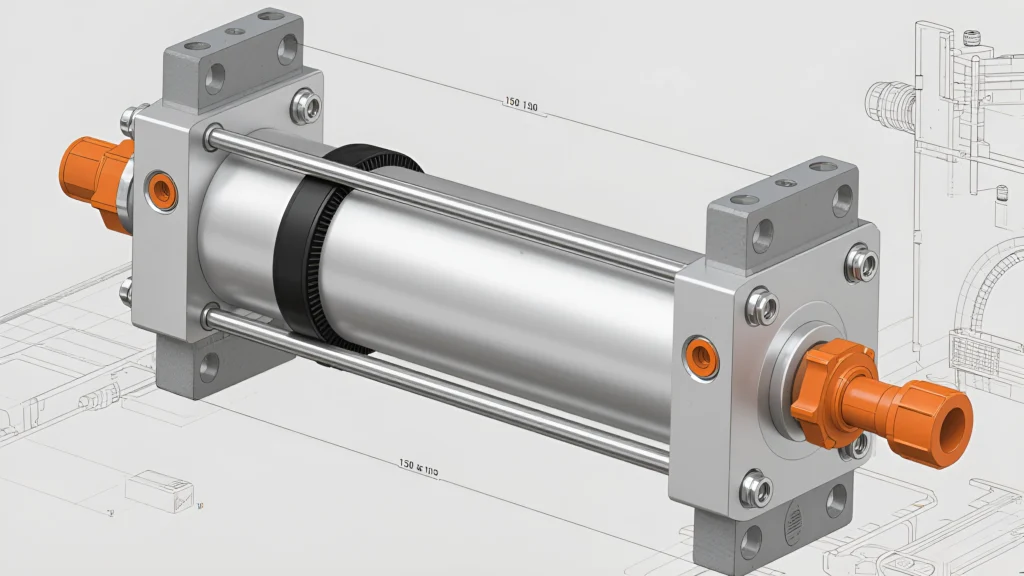

Double Acting Hydraulic Cylinders

Double acting hydraulic cylinders, on the other hand, can generate force in both the extend and retract directions. This makes them suitable for more complex operations in water dams, such as precisely controlling the opening and closing of radial gates. They offer greater flexibility and control compared to single acting cylinders.

Telescopic Hydraulic Cylinders

Telescopic hydraulic cylinders are designed to provide a long stroke in a compact package. In water dams, they can be used for applications where a large range of motion is needed, such as in the operation of certain types of floodgates. Their multi-stage design allows them to extend and retract smoothly over long distances.

Challenges in Water Dam Hydraulic Cylinders Design

Harsh Environmental Exposure

Continuous moisture, flooding, and temperature changes.

Need for corrosion-resistant materials like stainless steel or special coatings.

High Load Requirements

Operating massive gates weighing several tons.

Requires large bore cylinders with high-pressure capability (up to 350 bar or more).

Long Stroke & Stability

Strokes of several meters are common.

Cylinder design must prevent rod bending or misalignment.

Safety and Redundancy

Cylinders must function in emergency situations (flood gates opening).

Often integrated with backup hydraulic power units (HPUs).

Applications of Water Dams Hydraulic Cylinders

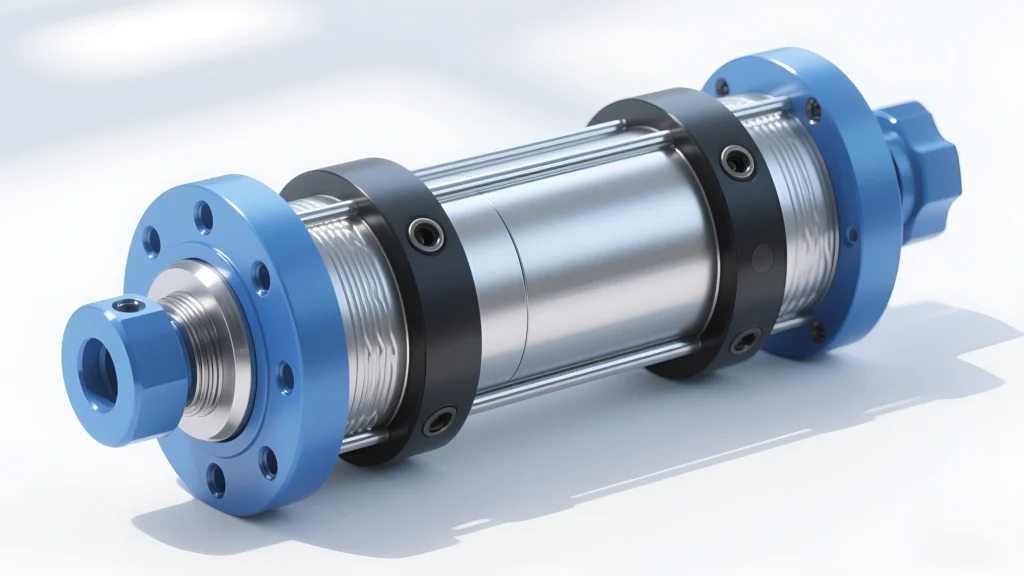

Key Features of JW Hydraulic Water Dam Hydraulic Cylinders

Custom Bore Sizes – up to 1,200 mm for extreme force requirements.

Long Stroke Capability – engineered for 1–10+ meters stroke length.

High-Strength Materials – carbon steel with special coatings, stainless steel, duplex steel for maximum corrosion resistance.

Chrome-Plated or Induction-Hardened Rods – extended wear resistance in harsh environments.

Heavy-Duty Seals – resistant to silt, debris, and extreme weather conditions.

Optional Position Sensors – for real-time gate position monitoring.