The Rise of Intelligent Hatch Cover Hydraulic Cylinders

Intelligent Marine Hydraulic Cylinders for Advanced Ship Hatch Cover Systems

Meta description

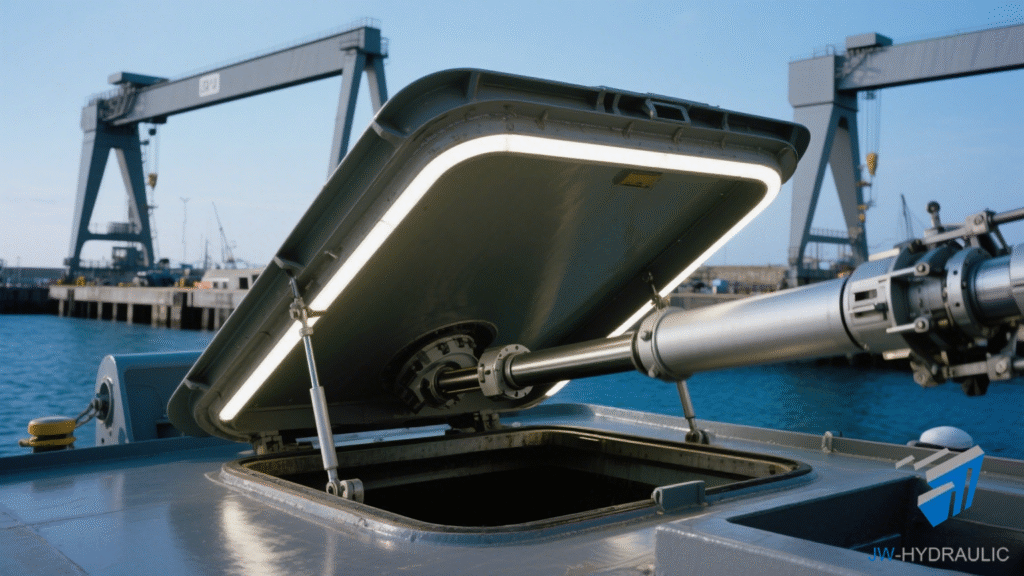

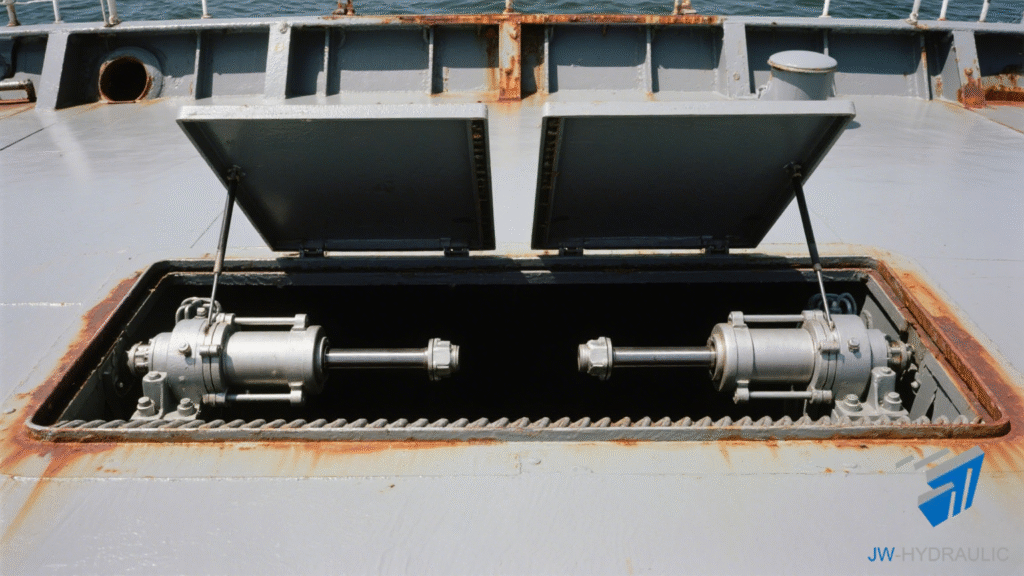

In the maritime industry, safety, efficiency, and automation are becoming increasingly critical. One of the key innovations driving these changes is the development of intelligent hatch cover hydraulic cylinders. These advanced hydraulic systems are revolutionizing how ship hatch cover systems operate, ensuring greater reliability and performance.

The Growing Demand for Intelligent Ship Equipment

The global ship market has been steadily gravitating towards intelligent equipment in recent years. According to market research, the connected ship market size, which encompasses a wide range of intelligent systems on ships, was valued at USD 7.66 billion in 2023. It is projected to grow from USD 8.11 billion in 2024 to USD 12.83 billion by 2032, with a compound annual growth rate (CAGR) of 5.9% during the forecast period (2025 – 2032). This growth is indicative of the increasing demand for efficient and digitally – enabled maritime operations.

Smart technology systems in marine hatch covers are creating new market opportunities. Features such as remote monitoring, AI – based load distribution sensors, real – time water ingress detection, and automatic hydraulic sealing systems are highly favored by shipping operators and defense fleets. The use of intelligent ship technology and IoT – based systems is paving the way for the automation of digital diagnostic and automated maintenance systems in hatch covers. This, in turn, is reducing ship maintenance costs and enhancing vessel efficiency.

How Intelligent Hydraulic Cylinders Work

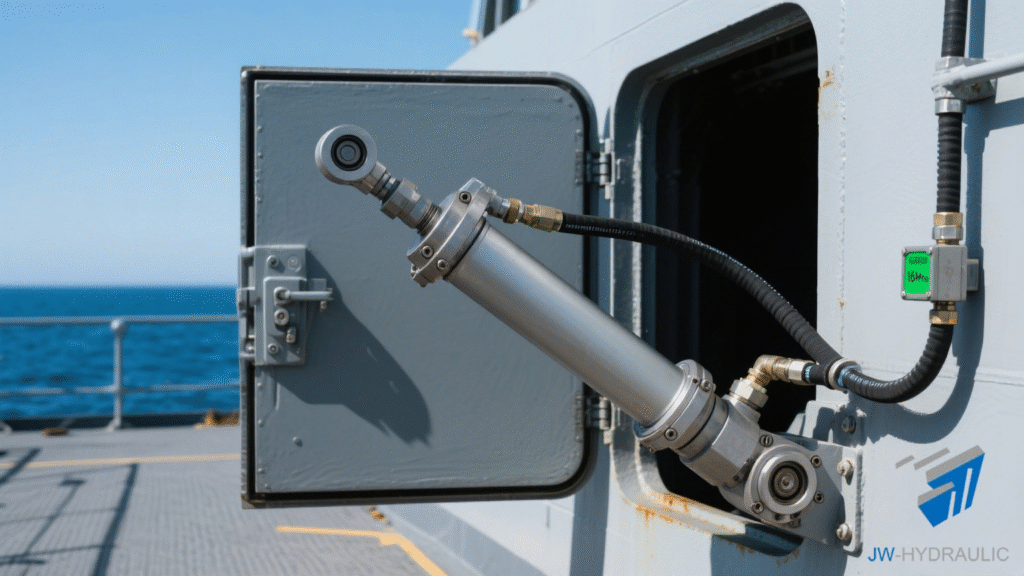

Intelligent Hatch Cover Hydraulic Cylinders are equipped with an array of sensors that play a crucial role in their operation. These sensors are designed to monitor various parameters of the cylinder’s working state in real – time. For example, pressure sensors keep a close eye on the hydraulic pressure within the cylinder. Any deviation from the optimal pressure range could indicate issues such as leaks in the hydraulic system or problems with the pump. By continuously monitoring the pressure, the system can detect potential problems early on and take corrective actions.

Temperature sensors are also an integral part of these intelligent cylinders. They monitor the temperature of the hydraulic fluid and the cylinder components. Overheating can be a sign of excessive friction, which could be caused by worn – out seals or misaligned parts. By detecting abnormal temperatures, the system can alert the crew or even initiate automatic cooling measures if available.

Position sensors are used to track the position of the piston within the cylinder. This information is vital for ensuring that the hatch cover opens and closes smoothly and accurately. In case the piston gets stuck or moves erratically, the position sensor can quickly detect the anomaly and trigger an alarm.

All the data collected by these sensors is transmitted to a central control system. This system uses advanced algorithms to analyze the data and make informed decisions. For instance, if the pressure sensor detects a sudden drop in pressure, the control system can determine whether it is due to a minor leak that can be fixed during the next maintenance check or a major leak that requires immediate attention.

Benefits of Intelligent Monitoring and Control

Enhanced Safety

One of the most significant advantages of intelligent monitoring and control of hatch cover hydraulic cylinders is the improvement in safety. In the past, many accidents related to hatch covers were caused by sudden failures during operation. With the real – time monitoring capabilities of intelligent hydraulic cylinders, potential failures can be predicted and addressed before they occur. For example, if the sensors detect a slow degradation in the performance of a seal, maintenance can be scheduled proactively, reducing the risk of a sudden seal failure that could lead to a hatch cover malfunction while the ship is at sea.

In addition, in case of an emergency, the intelligent control system can quickly respond. For instance, if there is an unexpected increase in the load on the hatch cover due to rough seas, the system can automatically adjust the hydraulic pressure to ensure that the hatch cover remains secure.

Increased Efficiency

Intelligent hydraulic cylinders contribute to increased operational efficiency in several ways. Firstly, they enable remote operation and monitoring. Ship operators can control the opening and closing of hatch covers from a control room on the ship or even remotely from shore in some advanced systems. This reduces the need for crew members to be physically present near the hatch covers during operation, saving time and effort.

Secondly, the real – time data provided by the sensors allows for better decision – making. Ship managers can analyze the data to optimize the operation of the hatch covers. For example, if the data shows that a particular hatch cover is consuming more energy than usual during opening and closing, adjustments can be made to the hydraulic system settings or the mechanical components can be inspected for signs of wear.

Cost Savings

The predictive maintenance capabilities of intelligent hydraulic cylinders result in significant cost savings. By detecting potential problems early, ship operators can avoid costly breakdowns and emergency repairs. Instead of waiting for a component to fail completely and then having to replace it at a high cost, maintenance can be scheduled during planned maintenance intervals.

Moreover, the increased efficiency in operation also leads to cost savings. Reduced energy consumption due to optimized operation and fewer instances of downtime mean that the overall operating costs of the ship are lowered.

The Future of Intelligent Hatch Cover Hydraulic Cylinders

The future of intelligent hatch cover hydraulic cylinders covers looks promising. As technology continues to advance, we can expect to see even more sophisticated sensors and control systems. For example, the integration of artificial intelligence and machine learning algorithms will enable the control system to not only detect problems but also learn from past experiences and make more accurate predictions.

There will also be a greater focus on improving the reliability and durability of these intelligent components. Manufacturers will invest in research and development to develop new materials and manufacturing techniques that can withstand the harsh marine environment better.

In addition, as the demand for autonomous ships grows, intelligent hydraulic cylinders will play a crucial role. In an autonomous ship, the hatch cover operation needs to be highly reliable and automated. Intelligent hydraulic cylinders with their advanced monitoring and control capabilities will be essential for ensuring the smooth operation of hatch covers in such vessels.

In conclusion, intelligent hydraulic cylinders are set to revolutionize the way ship hatch covers operate. With their ability to provide real – time monitoring, enhance safety, increase efficiency, and save costs, they are becoming an indispensable part of modern ship design and operation. As the global shipping industry continues to embrace digital transformation, the adoption of intelligent hydraulic cylinders in ship hatch covers is only expected to increase.