Preventing Hydraulic Cylinder Failure: How to Address Piston Rod Corrosion and Scratches

Description

Let’s go-to podcast for practical tips on maintaining hydraulic systems and avoiding costly downtime. Today we’re tackling a common but often overlooked issue: piston rod corrosion and scratches.

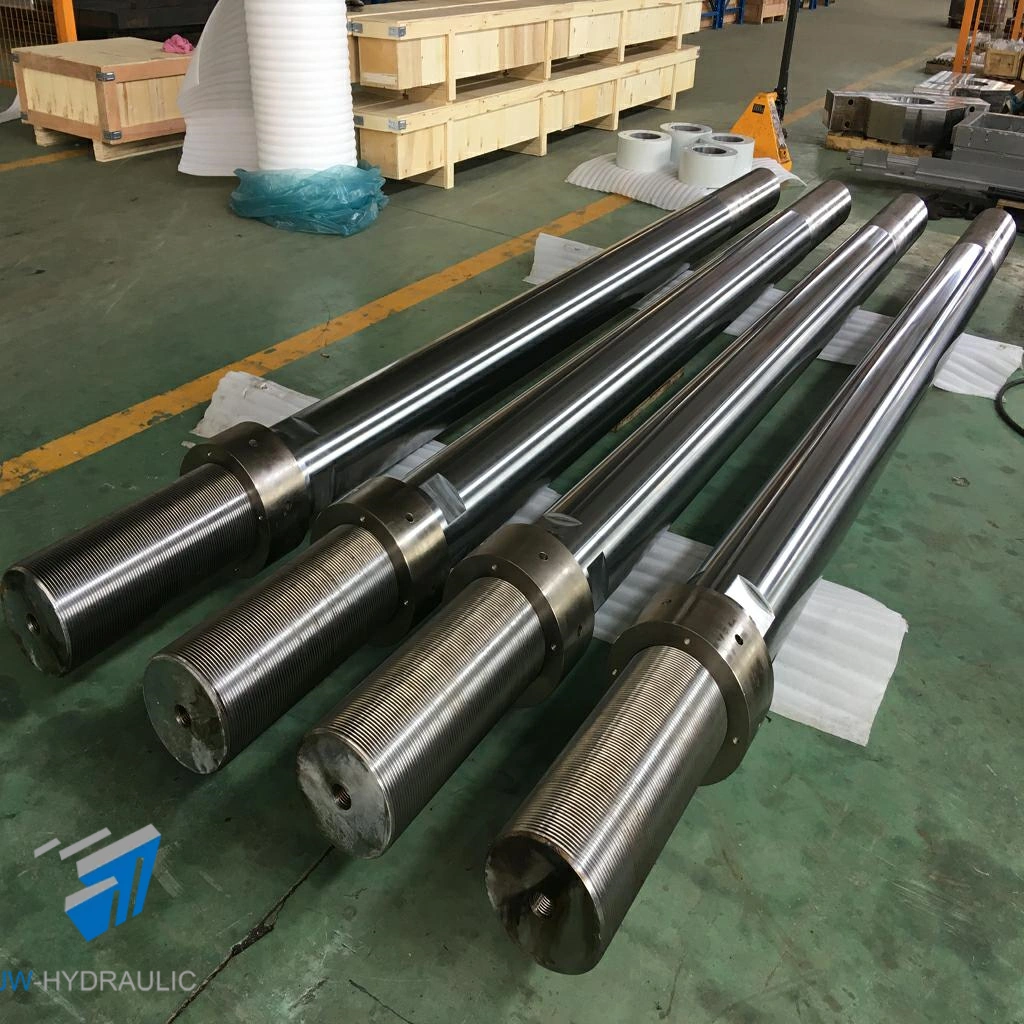

The piston rod is the backbone of your hydraulic cylinder, responsible for transferring force and motion. But when its surface gets damaged—whether from rust, scratches, or flaking chrome plating—it’s bad news.

Common Problem: Corrosion and Damage on Piston Rods

Visible rust or pitting on the rod’s surface.

Scratches or grooves caused by external impacts.

Flaking chrome plating, exposing the vulnerable metal underneath.

If ignored, these issues can lead to seal failures, fluid leaks, and even complete cylinder breakdowns.

Why Does This Happen? Let’s Break It Down

What causes piston rods to corrode or get scratched? Three key culprits:

1️⃣ Harsh Environments: Exposure to moisture, saltwater, or corrosive chemicals (like fertilizers or industrial solvents) eats away at the rod’s protective layers.

2️⃣ Physical Impacts: Accidental collisions with hard objects—think rocks, tools, or debris in industrial settings—leave scratches that compromise the rod’s integrity.

3️⃣ Contaminants in Seals: Dust, grit, or metal shavings entering the seal area act like sandpaper, grinding against the rod during operation.

Protect Your Piston Rods and Save Money

1️⃣ Upgrade to Corrosion-Resistant Coatings

Opt for hard chrome-plated rods—they’re the gold standard for durability and corrosion resistance.

For extreme environments (think marine or chemical industries), consider stainless steel rods or advanced coatings like nickel-chromium.

2️⃣ Add Protective Accessories

Install rod wipers or scrapers to keep contaminants out of the seal area.

Use protective bellows or covers to shield rods from impacts and environmental exposure.

3️⃣ Implement a Maintenance Routine

Clean rods regularly with a soft cloth and mild solvent to remove dirt and moisture.

Inspect for early signs of damage—catching small scratches early prevents major repairs later.

4️⃣ Train Your Team

Teach operators to avoid collisions and report issues promptly.

Store spare rods properly to prevent pre-installation corrosion.

Real-World Impact: Why This Matters

Still on the fence about prioritizing piston rod care? Consider this: A single corroded rod can cause cascading failures—contaminated hydraulic fluid, blown seals, and unplanned downtime. Replacing an entire cylinder costs thousands… while proactive maintenance costs pennies in comparison.

Conclusion

Learn how to combat piston rod corrosion and scratches in hydraulic cylinders! Discover causes, solutions like hard chrome plating, and maintenance tips to avoid costly downtime.

Protect your piston rods with the right coatings, add physical safeguards, and stick to a maintenance schedule. Small steps today prevent big headaches tomorrow!

Keywords Integrated

Hydraulic cylinder maintenance

Piston rod corrosion prevention

Hard chrome plating benefits

Hydraulic cylinder repair tips

Preventing piston rod scratches

Industrial hydraulic solutions